Our Products

Technology Leader and Total Integrated Solution Provider delivering high-precision measurement and control devices.

Flow Meters

Ultrasonic flow measurement is among the best & most accurate technology available these days. It is widely accepted across industries due to its non-cohesive nature with the flow media and immunity to high magnetic field zones.

Our Shenitech ultrasonic flow meters work on the Transit-Time principle, ensuring ±1% accuracy for domestic water, dirty water with high TDS, sewerage, and effluent treatment applications.

Key Transducer Types

Clamp-on

Non-intrusive installation without pipe cutting. Portable and versatile for DN25~DN6,000.

Insertion

Excellent long-term stability and signal strength for liquids with solids. Pipe size ≥DN80.

Inline

Pre-programmed factory calibration for plug-and-play accuracy. DN10~DN500.

.jpg)

Benefits & Features

| Feature | Benefit |

|---|---|

| Low Maintenance | No moving parts ensures long-term reliability. |

| High Accuracy | Accurate up to ±1% with OIML R49 standard. |

| Standards | CE Approval and Tamper-proof design. |

| Integration | Analog (4-20mA), Modbus RS-485, and M-Bus outputs. |

BTU Meters

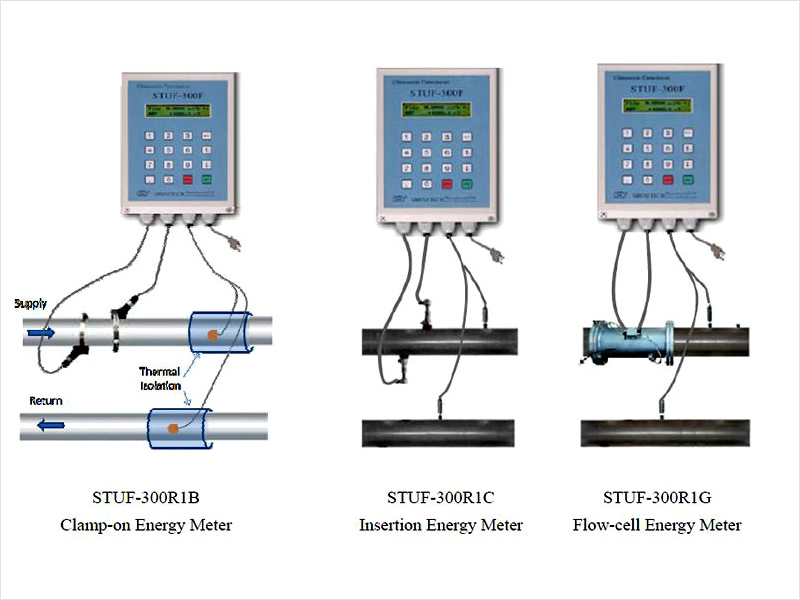

Clamp-on Ultrasonic BTU Meters

The STUF 300R thermal energy meter provides abundant capabilities for accurate measurement of liquid-based thermal energy production and transfer systems.

Consisting of a high-performance flowmeter and a pair of PT100 temperature sensors, it measures the supply and return flow temperatures to deduce energy consumption rates instantly.

Inline BTU Meters

Our inline BTU meters are highly integrated, simple to install, and provide precise billing data for district heating/cooling networks.

Technical Performance

| Specification | Details |

|---|---|

| Fluid Temperature | Wide range support for chilled and hot water loops. |

| Sensors | High-precision matched PT100 pairs. |

| Data Logging | Internal totalizers for volume and energy accumulation. |

| Communication | Compatible with BMS and remote billing software. |

Variable Air Volume (VAV) Boxes

Our VAV terminal units regulate conditioned supply-air into occupied spaces, ensuring precise temperature control while minimizing fan power requirements.

Operation Principle

The air supply increases as the cooling load increases and decreases as the load drops. This modulation saves significant energy compared to constant-volume systems.

Single Duct

Standard cooling/heating modulation for commercial zones.

Dual Duct

Mixing hot and cold air streams for superior comfort control.

Control Valves & Actuators

Forming the "heart" of any HVAC system, we provide world-renowned Siemens make valves and actuators for cost-effective and reliable control.

Valve Portfolio

- PICV: Pressure Independent Control Valves for optimized hydronic balancing.

- Globe Valves: High-precision linear control for steam and water.

- Magnetic Valves: Ultra-fast response for critical applications.

- Butterfly Valves: Large-scale flow control with motorized actuation.

Manual Valves & Strainers

Essential isolation and protection components for any industrial or HVAC piping network. Built for durability and ease of operation.

Ball Valves

Quarter-turn isolation for high-pressure loops.

NRV Valves

Ensuring unidirectional flow and preventing backflow.

Y-Strainers

Protecting downstream equipment from debris and scale.