Services - Ninth Wave Technologies

Technology Leader and Total Integrated Solution Provider

Service Capabilities

End-to-end support that keeps your HVAC and metering systems reliable, efficient, and compliant.

VAV AMC & Refurbishment

Survey, validation, modernization, and on-site rectification for existing VAV systems.

Explore VAV ServicesBTU Meter AMC

Quarterly health checks, on-site calibration, and proactive maintenance planning.

Explore BTU AMCCalibration Facility

Certified BTU meter calibration and validation at our facility.

Request CalibrationService Journey

Click each step to explore how we deliver reliable AMC and refurbishment outcomes.

VAV AMC & Services

Ninth Wave has launched a new initiative of refurbishing VAV equipment and systems within its service division. A comprehensive package which includes initial survey, VAV unit validation, report and recommendations, followed on, if required, by on-site rectification, modernisation and installation. With this single point responsibility, all work can be undertaken to suit the clients’ specific requirements bearing in mind that very often the offices are still occupied.

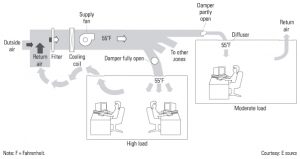

Variable Air Volume Systems Currently available air distribution components, controls, and design strategies offer much more efficient designs than those installed and operating in many existing buildings. Today’s VAV systems can handle changing load requirements by varying the amount of heated or cooled air circulated to the conditioned space in response to varying heating or cooling loads. This reduces fan power requirements, which saves energy and costs.

VAV-systems work either by opening or closing dampers or by modulating the airflow through mixing boxes powered by VAV fans as loads in various zones of the building change.

How it Works:

If, for example, more cooling in an area is required, the damper to that area is opened wider, increasing the flow of cold air until the desired temperature is reached. As the damper opens, static pressure in the duct drops, signaling the fan to increase air delivery. Conversely in this same example, if an area is too cool, the damper is slowly closed, reducing the flow of cold air.

Variable-speed drives (VSDs):

Used in combination with variable-speed drives (VSDs), this reduction in flow results in a reduction in the fan power needed, saving energy. Converting an existing constant-volume system to a VAV system is a popular option for many building owners, because it allows the system to turn itself down in response to changing demand.

VAV Terminal units:

Variable Air Volume terminal units regulate the flow of conditioned supply-air into occupied spaces, to assure that comfortable temperature levels are maintained.

BTU Meter AMC Services

Calibration Services

We provide a BTU meter Calibration Facility at our works.

Contact NowAnnual Maintenance Contract (AMC)

We undertake Annual Maintenance Contract (AMC) for BTU Meter at a nominal cost. In this contract, we proactively visit the site, every quarter. During every visit, we check the health of the Flowmeters and carry-out, on-site calibration once in a year.